Choosing the correct magnetic material for your application is perhaps the most critical design decision that determines your product’s maximum performance and ultimate success.

We help our customers make informed decisions regarding structural integrity, coercivity, energy product, cost, longevity, based on the environment in which the magnet or assembly will operate.

This information determines the best performing material for your application.

All magnetic materials are licensed

We offer only the highest quality magnetic material available

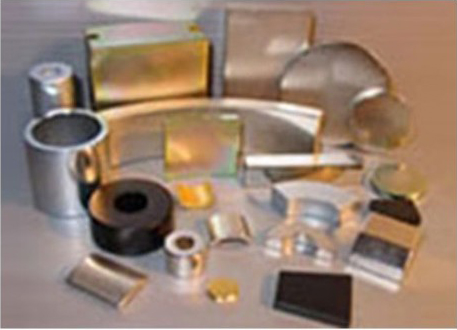

Available magnetic materials include:

- SmCo

- Cemented Carbides

- Hard Ferrite

- Soft Ferrite

- NdFeB

- Fe-Co

- Fe-Ni

- SmFeN

- Fe-Si

- Alnico

- Austenitic steels

- Semi-hard materials

- Iron and Carbon steels

- Nano-Crystalline Alloys

- Amorphous alloys

- Bonded magnets

Coatings:

Most common:

- Ni-Cu-Ni

- Epoxy

Other coatings available are:

- Zinc

- Titanium Nitride

- IVD

- Aluminum

- Parylene

- Tin

- Silver

- Gold

Tolerances:

- Typical tolerance for ground/coated/plated magnets is +/- .005”

- Ni coated magnets can be held to +/- .003” without cost implications

- We can hold tolerances up to +/- .0005”